How Turnkey PCB Assembly Accelerates IoT and Smart Device Manufacturing

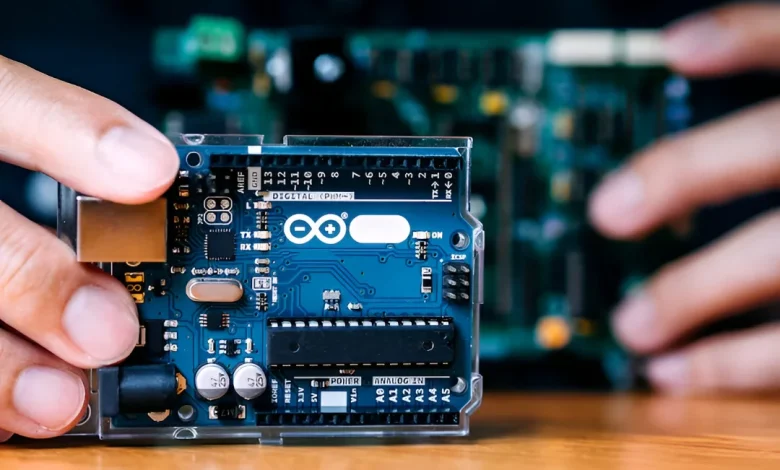

The Internet of Things (IoT) has transformed how devices interact with the world. From smart home systems and wearable technology to industrial sensors and connected healthcare equipment, IoT products are becoming an essential part of everyday life. Behind every successful IoT device is a reliable printed circuit board that must perform consistently, efficiently, and at scale.

Manufacturing IoT hardware, however, is far more complex than traditional electronics production. Tight form factors, mixed-signal designs, power efficiency requirements, and long-term reliability all create unique challenges. To manage these complexities, many IoT manufacturers rely on turnkey PCB assembly as a practical and scalable manufacturing approach.

Understanding the Unique Challenges of IoT Manufacturing

IoT devices differ from conventional electronics in several important ways. They are often designed to operate continuously, connect wirelessly, and function in diverse environments. These characteristics introduce manufacturing challenges such as:

- Compact and high-density PCB layouts

- Mixed analog, digital, and RF components

- Low-power and energy-efficient design requirements

- Long operational lifespans

- Frequent design revisions and feature updates

Managing these requirements with fragmented manufacturing models can slow development and increase failure risks. Turnkey PCB assembly helps address these challenges by providing an integrated and controlled production process.

Why Traditional Manufacturing Models Fall Short for IoT

In traditional PCB manufacturing, different vendors may handle sourcing, fabrication, assembly, and testing. While this model may work for simpler products, it often struggles to support IoT development.

Common problems include:

- Poor coordination between design and assembly

- Delays caused by component availability

- Inconsistent quality across production batches

- Limited testing coverage for real-world conditions

- Difficulty scaling production as demand grows

For IoT companies competing in fast-moving markets, these issues can delay launches and weaken product reliability.

How Turnkey PCB Assembly Supports IoT Development

Turnkey PCB assembly offers a unified manufacturing model where a single provider manages the entire production workflow. This approach is especially valuable for IoT products that require tight integration between design, sourcing, and assembly.

By centralizing responsibility, turnkey PCB assembly ensures that design intent is preserved throughout manufacturing. Potential issues are identified early, and solutions are implemented without lengthy back-and-forth between suppliers.

Faster Prototyping for IoT Innovation

Speed is critical in IoT development. New features, connectivity standards, and user requirements evolve rapidly, and manufacturers must adapt quickly.

Turnkey PCB assembly enables faster prototyping by:

- Reviewing designs for manufacturability

- Sourcing components efficiently

- Producing small batches for validation

- Supporting quick design iterations

This rapid prototyping cycle allows IoT companies to test concepts, refine performance, and move toward production without unnecessary delays.

Managing Complex Component Sourcing

IoT devices often rely on a wide range of components, including microcontrollers, sensors, wireless modules, and power management circuits. Sourcing these components consistently can be challenging, especially during shortages.

Turnkey PCB assembly providers manage component sourcing through verified supply networks. This reduces the risk of counterfeit parts, mismatched specifications, or sudden shortages. For IoT products that depend on stable connectivity and performance, reliable sourcing is essential.

Power Efficiency and Assembly Precision

Many IoT devices are battery-powered and expected to operate for months or even years without maintenance. Assembly precision directly affects power efficiency and reliability.

Turnkey PCB assembly supports precise assembly by:

- Ensuring accurate component placement

- Maintaining consistent soldering quality

- Reducing defects that cause power leakage

- Supporting design optimization for low-power operation

These factors contribute to longer battery life and improved user experience.

Wireless Performance and Signal Integrity

Wireless communication is a core feature of IoT devices. Poor assembly practices can negatively affect signal integrity and connectivity performance.

Turnkey PCB assembly providers work closely with design and testing teams to ensure that RF components, antennas, and sensitive circuits are assembled correctly. This coordination helps maintain consistent wireless performance across production batches.

Scaling IoT Production Without Losing Quality

Many IoT products start with small pilot runs and later scale to mass production. Scaling too quickly without proper controls can introduce quality issues.

Turnkey PCB assembly supports smooth scaling by applying the same production standards regardless of volume. Whether producing hundreds or thousands of units, the process remains controlled and predictable.

A reliable manufacturer offering Turnkey PCB Assembly Services helps IoT companies scale production while maintaining performance and reliability.

Testing for Real-World IoT Conditions

IoT devices often operate in challenging environments, including temperature variations, humidity, and continuous usage. Testing must account for these conditions.

Turnkey PCB assembly integrates testing throughout the production process, including:

- Electrical and functional testing

- Connectivity verification

- Visual and automated inspections

- Process validation checks

This structured testing approach helps identify issues early and ensures that devices perform reliably in real-world applications.

Supporting Continuous Product Updates

IoT products frequently receive updates, whether to add new features, improve performance, or address component changes. Managing these updates requires flexible manufacturing support.

Turnkey PCB assembly simplifies revision management by:

- Tracking design changes

- Managing component substitutions

- Applying consistent validation procedures

- Reducing errors during updates

This flexibility allows IoT companies to evolve products without disrupting production.

Long-Term Reliability for Connected Devices

Reliability is especially important for IoT devices deployed in remote or critical environments. Failures can lead to data loss, service disruptions, or safety risks.

Turnkey PCB assembly emphasizes quality consistency and process control, helping ensure that devices meet long-term reliability expectations. Fewer failures translate into lower maintenance costs and stronger customer trust.

Cost Control in IoT Manufacturing

IoT products often compete in cost-sensitive markets. Efficient manufacturing is essential to maintain profitability.

Turnkey PCB assembly helps control costs by:

- Reducing rework and scrap

- Streamlining logistics

- Improving production efficiency

- Supporting predictable pricing

Companies using Turnkey PCB Assembly Services can balance performance requirements with cost constraints more effectively.

Enabling Global IoT Deployment

Many IoT products are designed for global deployment. Manufacturing consistency and compliance are important for meeting diverse market requirements.

Turnkey PCB assembly’s providers are experienced in supporting global manufacturing needs, helping IoT companies prepare products for wider distribution without unnecessary complexity.

Manufacturing Expertise Behind IoT Success

Manufacturers like globalwellpcba.com focus on delivering end-to-end PCB assembly solutions that align with the specific needs of IoT and smart device companies. Their structured workflows, engineering support, and quality focus help ensure reliable production from prototype to mass manufacturing.

Final Thoughts

IoT and smart devices demand a manufacturing approach that is flexible, reliable, and scalable. Fragmented production models often struggle to meet these requirements, leading to delays, quality issues, and increased costs.

Turnkey PCB assembly offers a practical solution by integrating design support, sourcing, assembly, testing, and scaling under one system. For IoT companies aiming to innovate quickly while maintaining quality and reliability, turnkey PCB assembly provides a strong foundation for long-term success.

By simplifying complexity and supporting continuous improvement, turnkey PCB assembly enables IoT manufacturers to focus on what matters most—building connected products that perform reliably in the real world.