AG Coating vs Matte Finish: What’s Best for Eye Comfort?

From grinding on a 144Hz gaming monitor to chasing deadlines on an OLED 120Hz monitor, screens are a must for most people nowadays for AG Coating vs Matte Finish. We stare at these displays for hours every day, whether to work or play, do schoolwork, or just to relax. And while the right panel technology is important, there is one factor most of us don’t give a second thought to when buying a new display: the screen surface.

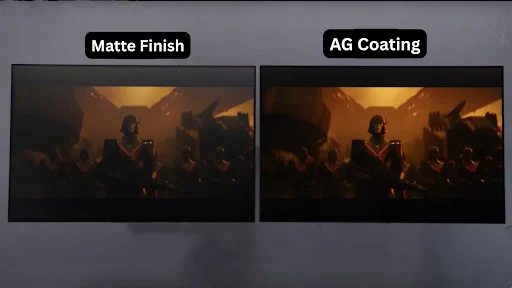

Two popular types of finishes you will often encounter are AG coating and Matte. While both reduce reflections and glare and aim to protect your eyes, they do so in different ways. The differences in texture, appearance, and display performance are also key in choosing which one is better for you.

In this guide, we will walk you through what each of these screen coatings is, how they compare in reducing glare, and which is more suited to certain use cases. Find out which option will give you the most comfort, especially when it comes to eye comfort, whether you are editing videos on an OLED 120Hz monitor or working in the office.

Spotlight on brilliance—our Related Post is today’s must-read moment!

AG Coating vs Matte Finish: Let’s Understand First

Matte vs AG Coating: How Are They Different?

The most basic difference between these two types of coatings is how they reduce glare. A matte finish screen has a diffused texture that scatters and absorbs reflected light. This non-glossy surface minimizes glare by preventing direct reflection from reaching your eyes.

On the other hand, AG coating is a layer applied on top of the display to help minimize glare, while maintaining brightness and contrast. It does so by subtly breaking up the reflection without muddying the display colors or clarity.

Matte screens provide maximum glare reduction, making them ideal for bright environments with strong overhead lighting or natural light. They also retain less fingerprints and smudges than glossy or AG-coated displays. However, Matte screens sacrifice some color depth and image sharpness for comfort.

AG coatings strike a balance between crisp visuals and reflection control. Displays with AG coating still offer good color vibrancy, contrast, and brightness, so they look excellent and are easy to read for the eyes. This surface finish has a subtle texture that provides good glare reduction, without compromising on the clarity.

AG Coating vs Matte Finish: Eye Strain Relief

Both Matte and AG coatings help reduce eye fatigue, but in slightly different ways. The amount of eye strain relief you get from either screen surface will also depend on other factors such as ambient lighting conditions and content type.

Here are some of the key reasons screen coatings matter for eye strain:

Glare and Reflections

Flickering glare and harsh reflections from windows or lamps cause discomfort and distract your eyes. Screen coatings cut down these reflections, especially when your display is off-axis.

Brightness and Contrast

AG coatings or Matte surfaces provide a more balanced brightness and contrast output. This puts less strain on the eyes to perceive content or text.

Image Clarity

AG-coated displays have a sharper picture than Matte ones, which helps your eyes focus and relax.

Overall Visual Comfort

Better reflection control and clarity help minimize distractions, so you can work or play longer without getting headaches or eye fatigue.

Eye Care and Health

Long-term exposure to harsh glare and blue light can damage your eye health. The right screen coating plus settings such as lower brightness, blue light filters, and a comfortable distance can help protect your eyes.

Matte vs AG: Which Is Best for Your Eyes?

Eye strain is not just caused by surface coatings, but also screen brightness, contrast, and blue light levels. The type of finish and its glare-reducing capabilities play an important role in the overall comfort, though.

One type is not objectively “better” for eye comfort than the other. Matte screens shine in well-lit environments with plenty of sunlight or overhead lights. AG coatings provide good glare reduction, while retaining good brightness, sharpness, and color accuracy, for more varied lighting.

Use Cases and Recommendations

Matte or AG: Which Surface for What Work?

The best display finish will also depend on how you use it. Consider what type of tasks you do most on your monitor, and which environment you use it in, to narrow down your options.

Matte vs AG: Use Case Examples

Here are some use cases and recommendations for each surface type:

Matte for Office Work and Study:

A matte finish is well-suited for working in bright rooms or near windows. It provides superior glare reduction so that reflections from overhead lamps or sunlight don’t distract your eyes and compromise your focus. The even, diffused texture of matte screens makes them comfortable to look at for long typing or reading sessions.

AG Coating for Gaming and Multimedia:

Gamers need high refresh rates for fluid motion, color accuracy for immersion, and sharpness for reading game HUDs and spotting enemies. An AG-coated 144Hz gaming monitor provides these capabilities, while also cutting down on distracting glare or reflections. An OLED 120Hz monitor with AG coating is also good for creative work where color reproduction matters.

Matte for Bright Offices or Creative Jobs:

Jobs that involve image or video editing demand high contrast and color precision. An OLED 120Hz monitor with AG coating is a good fit since it offers glare control while also keeping those vibrant colors and deep blacks. You can also find matte versions of monitors with good IPS or OLED panels for creative work in bright offices.

AG Coating for General Home Use and Mixed Lighting:

A hybrid room or home office with varying light conditions is best suited to AG coating. It still cuts down on glare, while preserving color and sharpness like glossy screens.

AG Coating vs Matte Finish: Which Wins?

Both AG-coated and Matte screens offer benefits for reducing glare and eye fatigue. It is also a matter of preference and the kind of work you do. If you are a gamer or do media work, AG coatings are better. If you do regular office work or coding, a matte finish may be preferable.

If you use your Mini LED Gaming Monitor for varied activities in different lighting conditions, such as general home use or online meetings, either screen surface is suitable. An AG-coated display would be slightly more versatile, since it also provides good glare reduction.

Maintenance and Cleaning

AG Coating:

- Clean gently with microfiber cloths and soft brushes.

- Avoid using rough paper towels or cleaning products with harsh chemicals that can scratch the coating.

- Can attract more fingerprints and smudges, but these wipe off easily.

Matte Finish:

- Dust and dirt don’t stick to the screen as much.

- Fingerprints are less visible, but dust and dirt can be more noticeable.

- Can be cleaned with soft cloth or mild cleaning solutions.

Screen Coating: AG Coating vs Matte Finish

Here is a comparison table on key factors and differences between matte and AG coatings. These two options are designed for the same use case—eliminating glare and reflections, but they work in different ways and have their own trade-offs.

Factor

- Matte Finish

- AG Coating

- Texture

- Microscopically rough, scatters reflections

- Nano-roughness or microstructures that refract light

Glare Reduction

- Maximum glare reduction, almost 100%

- Up to 95% glare reduction (subject to light source intensity and angle of incidence)

Brightness

- Brightness is scattered and reduced, can look duller

- Retains screen brightness and sharpness

Image Clarity

- Colors appear less vibrant, softer image details

- Maintains original color vibrancy and sharp details

Ideal for Bright Environments

- Yes, matte surfaces work best for bright and sunny settings.

- Suitable for mixed lighting, though direct sunlight is still problematic.

Contrast

- Lower contrast than glossy screens

- Retains high contrast

- Clarity and Sharpness

- Moderate clarity and sharpness

- Retains sharp image quality

Color Fidelity

- Colors appear washed out

- Keeps accurate, vibrant colors

Eye Comfort

- Best for sunny rooms, offices with lots of windows

- Suitable for most environments, including offices, outdoors, etc.

Ideal Use Cases

- Office work, study, brightly lit rooms

- Gaming, media work, productivity work, outdoors

Frequently Asked Questions

Does AG Coating Help Reduce Blue Light?

Yes, AG coatings also filter out some blue light, which helps lower eye fatigue and strain.

Is There a Difference Between AG and Matte?

AG is different from Matte in terms of the coating surface. While matte screens scatter and absorb reflected light to achieve glare reduction, AG-coated screens use microtextures or microprismatic structures to deflect and refract the light.

Can You Feel the Difference in Matte vs AG Coating?

Users can feel the difference in texture and appearance. Matte screens have a slightly rougher texture, while AG-coated screens feel smooth to the touch. The matte surface also diffuses light more, giving a softer, flatter appearance. In contrast, AG coatings are more subtle and less visible to the touch.

Is AG Matte Coating Better?

AG matte coatings are not necessarily better; they just serve different use cases. For pure glare reduction in very bright environments, matte surfaces work best. But AG coatings are good all-around coatings, providing glare reduction plus better clarity and color fidelity.

Final Words

AG-coated or matte screen surfaces each have their own advantages and use cases. Matte surfaces are best if your monitor is in a bright room with strong sunlight or overhead lights. AG coatings are better in general, if you use your screen for a mix of tasks, such as gaming, office work, and media consumption.

These coatings are not “better” or “worse” for eye comfort, only better or worse for different lighting environments. In the end, your eye comfort also depends on other display settings and factors, such as brightness, contrast, color accuracy, and blue light output. The most important thing is to keep your work setup ergonomic and eye-friendly.

If you are working at home or in an office, consider using an ergonomic adjustable desk. Investing in a good monitor is also important, as quality screen coatings can help a lot with eye comfort and eye fatigue relief. Look for a matte or AG-coated 144Hz gaming monitor or OLED 120Hz monitor that matches your needs, and enjoy comfortable long hours of work or play without stressing your eyes.

This one’s special—explore more at Merlin Physio packed with real inspiration!